FEEDERS FOR CATTLE

FEEDER FOR COWS IN TIE STALL

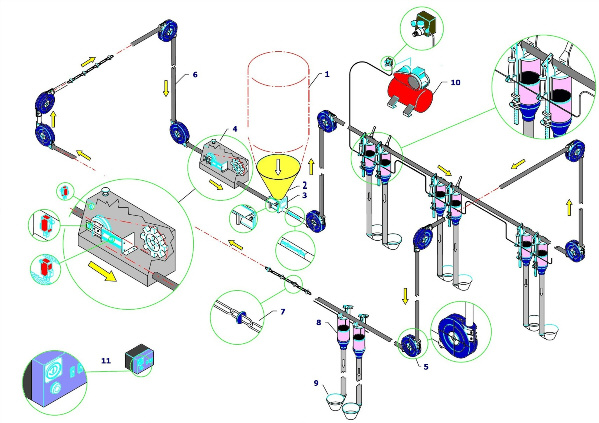

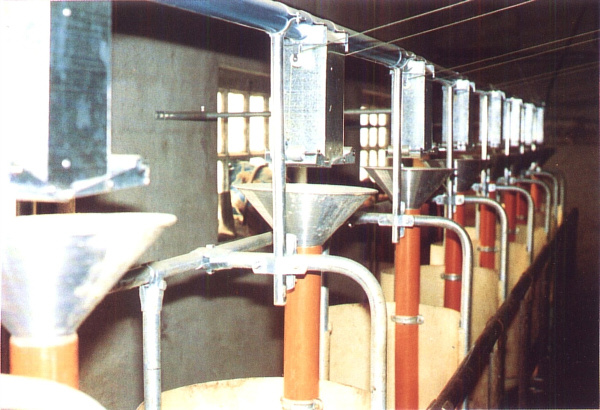

The validity of the initial project and the continuous improvement over time, have made feeder systems for cows in tie stall one of the strengths of our production. The automatic feeding in the tie stall stable eliminates waste and allows a drastic reduction in the consumption of animal feed. Targeted and precise rationing for each individual animal, combined with the ability to distribute the feed in frequent daily meals, significantly increases the production performance. Animal feed is normally conveyed with a disc chain system, which is well suited to any type of stable, overcoming any structural barrier.

FEEDER WITH SCHEDULED DOSING

The system with “programmed dosing” uses the same components of our systems for cows in tie stall.

At pre-set times the dispensers open simultaneously discharging a small amount of feed in the manger. This operation is repeated several times a day. The spiral or disc chain conveyor system fills the dispensers that remain waiting for the next feeding cycle. The animals of the group alternate in the rack, satisfying their individual feeding needs. The constant presence of feed in the rack induces the animals to a greater consumption of hay.

FEEDER FOR MILKING PARLOUR

Feeding in the milking parlour can be entrusted to the traditional system with mechanical opening. The operator in the milking parlour, by operating the opening levers, actuates the distribution of 1, 2 or 3 kg. of feed for each animal at his/her discretion.

For modern milking systems with electronic identification of animals, La Meccanica produces a feeder with low voltage electric rotary dispenser. The feeder can be easily interfaced with management software of the most important manufacturers of milking systems…

AD LIBITUM FEEDING SYSTEM FOR BEEF CATTLE

Beef cattle are usually fed using ad libitum systems. The feed is discharged into mangers or directly on the ground and kept constantly at the disposal of the animals. The system operation is controlled by a sensor placed at the end of the feeder line.

AUTOMATIC FILLING SYSTEM FOR FEEDING STATIONS

Automatic filling system for feeding stations The automatic filling of the feeding stations, depending on the design of the structure, can occur by a spiral or disc chain feed conveyor system. In the first case each hopper of each station is equipped with a level sensor. This is feasible even in systems with disc chain. As an alternative to the sensors, it is possible to set a timed charging of the stations. At predetermined time interval the system picks up the feed from the silo and transports it into the hoppers of the stations. When all the hoppers are full, the residue feed is discharged back into the silo.

AUTOMATIC GATES FOR FEEDING STATIONS

ProteCow ensures the cow protection during feeding in the station. At the time of distribution of the feed, the rear gates close slowly and protect the animal from the rest of the herd. After the meal is completed, the rear gates open automatically allowing the animal to go out.

At any time, the cow can in any case decide to leave the from the movable partition, exerting a slight pressure on the rear gates.

The system is controlled by an electronic board that allows to set a delay time for the gates opening, allowing the animal to complete the meal. The gates opening is entrusted to a robust pneumatic cylinder, which ensures its maximum reliability.